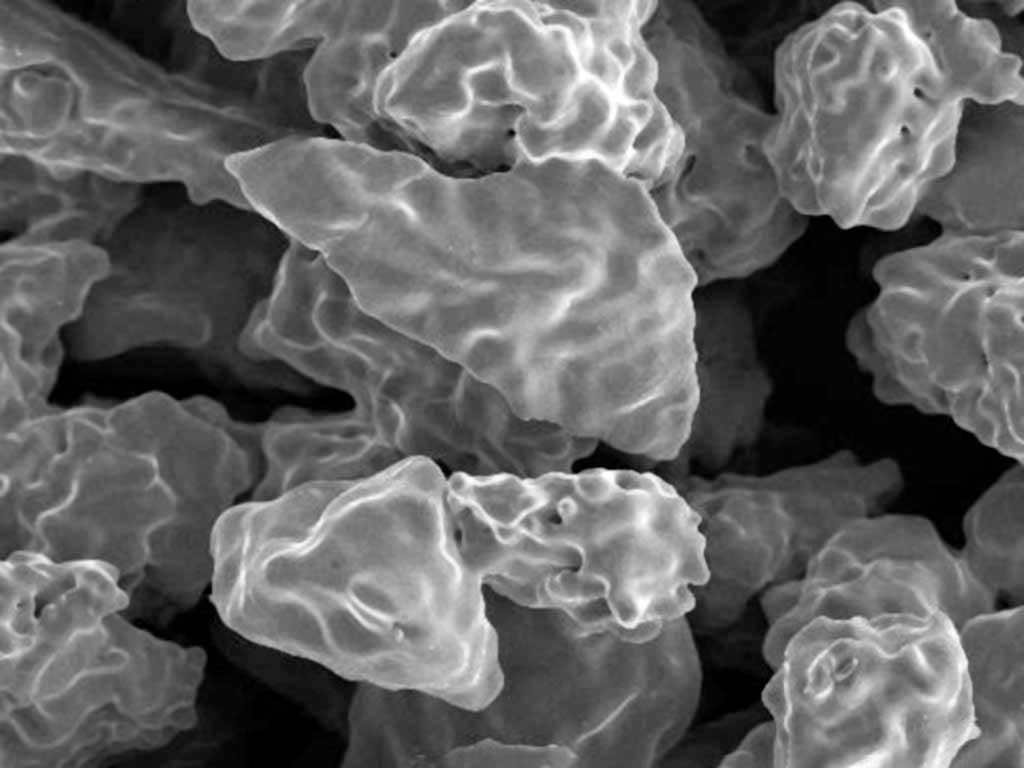

”Since we started one of our star products, which has led us to imports to a large part of the world, has been the coating of irregular particles. We are very proud of the welcome it has received in the sector to which we are dedicated, the health of people.

Recent studies have shown that its effectiveness, its adherence to the bone, it´s far superior to other coatings offered by the market: plasma, filament, 3D or HA. Its grip on the bone, of the 60% interconnected, is superior to all of them, surpassing by far the usual tendency of other suppliers to make it in 3D printers. At Biovac we have always put ahead the health of future patients, although despite being less profitable than other methods.

We know that the road is much more complicated so, that we will have to fight every day with a multitude of options that offer price, but in the long term the reward and tranquility of the job well done are there. Innovation does not always improve what already exists.

We invite you to know our irregular particle coating, a solution that is proven, tested and certified by numerous studies. It works and it will work, because if we are working on it since 1991 it will be for something.

In addition to the studies mentioned above, our strict ISO 9001 and ISO 13485 certifications guarantee that our coatings are validated following the procedures defined by the GHTF guide (Criteria for Reporting by Competent National Authorities). All this gives us momentum to continue the work of creating coatings that work, and help many people to live better, beyond the profitability that can offer us.

Comparison table

| Porosity | Pore size | Resiliency | Thickness | Rugosity | Material | Productivity [1] | Capacity | Others | |

| Plasma Spray | 15% not accessible to bone | 20 to 60 µm, not accessible to bone | 22MPa [2] | 0.08 – 0.5 mm | Rt: 70-300 µm [3] | Ti, Cr Co | High | Long series | |

| HA

| n/a [4] | n/a | 15 MPa [5] | 30 – 190 µm | Rt: 30-50 µm [6] | Onto Ti y Co Cr Mo | High | Long series | |

| Filament [13] (Zimmer) | 52%-58%. | 480-560 µm | >20MPa [7] | 1.6 mm | Only Ti | Medium | |||

| Porocoat (Microspheres) | 40% | 80-240 µm | >34.5 MPa | 0.15 – 1.8 mm | Rt: 100- 200 µm [8] | Ti, Cr Co | Medium | Medium series | |

| Porocoat (Irregular) | 60% | 160 – 260 µm | >34.5 MPa | 0.3 – 1.8 mm | Rt: 100-300 µm [9] | Ti, Cr Co | Medium | Medium series | |

| 3D

| 50-90% [10] | 300-900 µm | >20 MPa [6] | Whatever [11] | n/a [12] | Only Ti | Low (dust / residue finishing processes) | Small series | Knee Femoral / Custom Parts cannot be made |

[1] Taking into account ONLY the coating time. For the complete part, the classification would change.

[2] According to ISO 13179-1.

[3] It will depend on the thickness and size of the powder used.

[4] HA layers are not porous.

[5] According to ISO 13779-2.

[6] It actually reproduces the roughness of the substrate where it is deposited.

[7] In the absence of data and/or specific standard, this is the minimum that the coating would have to comply with according to the FDA.

[8] Measured values in our coating.

[9] Estimated value from microsphere data.

[10] According to the Corin catalogue.

[11] The coating can be designed with the desired value. Ball-like values can be given: 0.3 – 1.8 mm.

[12] No data. Since it is a regular geometric coating, rugosity cannot be considered relevant to porosity and pore size.

[13] Human spongy. Pore size: 400-500 µm. Pore volume: 60% -77%. CSTi ZIMMER Coating pore size: 480-560 µm. Pore volume: 52% -58%.